4 Column Deep Drawing Hydraulic Press

1. Stamping, forming, shallow, drawing, die spotting, molding and blanking etc.of metal and none metal parts.

2. Well suitable for pressing and forming of watch & clock parts, spectacle parts, tableware, photo frame, metal ornaments.

Main characteristics:

1. Ease operation: user friendly HMI, ease for setting parameters and recipe storage.

2. Control system: PLC + HMI (Siemens brand).

3. Pressing adjustment: high speed pressing setting, fulfill different pressing process technology requirement.

4. Accuracy monitoring: used for linear scale and pressure sensor to monitor the position and pressure, enhance the pressing accuracy.

5. Energy saving: high power motor fulfill high speed high pressure processing requirement, servo motor driving system can achieve energy saving 40 – 60%.

Detail

4 Column Deep Drawing Hydraulic Press

1. Advanced two way cartridge valve system ensures high reliability and much less hydraulic shock direction change.

2. Main hydraulic cylinder is made of alloy cast steel and it’s inner surface is finely grinded for life under high pressure.

3. Four columns are made of alloy steel with high tensile resistance and finely grinded and electro-plated with hard chrome.

4. Key hydraulic and electric units adopted are famous brands from Germany USA and Japan.

5. Fast approaching speed of movable working table creates higher production efficiency.

6. A hydraulic ejector is installed on movable working table for knocking out workpiece after drawing.

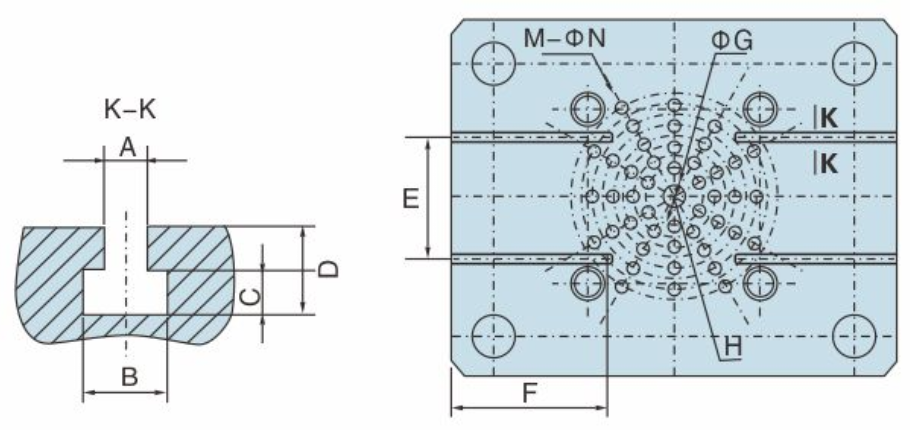

Above is size and distribution of working table, ejctor bar hole & T shape slot. Custom-made is accepted.

1. Deep drawing and forming of tableware, kitchenware, metal cover of electric motor, household appliances and lighting ware etc.

2. Trimming stamping deep drawing and edge-cutting of metal or none-metal workpiece.

Goodsjack 200 ton deep drawing hydraulic press for pot forming Goodsjack double acrtion deep drawing hydraulic press for food box forming

| Model | Units | Specifications | ||||||||||

| DSF-50 | DSF-120 | DSF-220 | DSF-220L | DSF-275 | DSF-350 | DSF-350L | DSF-500 | DSF-500L | DSF-600 | |||

| Main cylinder | Rated capacity | Ton | 35 | 85 | 160 | 160 | 200 | 260 | 260 | 350 | 350 | 420 |

| Max.stroke | mm | 350 | 450 | 560 | 560 | 560 | 560 | 560 | 600 | 600 | 700 | |

| Blank holding cylinder | Rated capacity | Ton | 15 | 35 | 60 | 60 | 75 | 90 | 90 | 150 | 150 | 180 |

| Max.stroke | mm | 175 | 200 | 260 | 260 | 260 | 600 | 260 | 300 | 300 | 350 | |

| Knocking out ejector | Rated capacity | Ton | 2 | 3 | 5 | 5 | 5 | 5 | 5 | 10 | 10 | 10 |

| Max.stroke | mm | 150 | 180 | 200 | 200 | 200 | 220 | 220 | 250 | 250 | 300 | |

| Open height | mm | 600 | 730 | 900 | 1000 | 900 | 900 | 900 | 1000 | 1200 | 1500 | |

| Height of fixed working table | mm | 990 | 1055 | 1080 | 1100 | 1100 | 1200 | 1200 | 1550 | 1600 | 1700 | |

| Approaching speed of M.W.T. | mm/s | 195 | 220 | 210 | 210 | 210 | 200 | 200 | 210 | 210 | 190 | |

| Drawing speed of M.W.T. | mm/s | 25 | 20 | 20 | 20 | 19 | 17 | 17 | 18 | 18 | 14 | |

| Returning speed of M.W.T. | mm/s | 180 | 220 | 200 | 200 | 200 | 165 | 165 | 190 | 190 | 180 | |

| Ascending speed of blank holding cylinder | mm/s | 120 | 50 | 120 | 120 | 115 | 160 | 160 | 85 | 85 | 75 | |

| Working table size available | (L-R) | mm | 500 | 500 | 710 | 900 | 800 | 900 | 1100 | 1050 | 1250 | 1400 |

| (F-B) | mm | 550 | 600 | 870 | 1100 | 900 | 1000 | 1250 | 1200 | 1500 | 1600 | |

| Over all dimension | (L-R) | mm | 1750 | 1990 | 20900 | 2280 | 2190 | 2200 | 2400 | 2970 | 3090 | 3690 |

| (F-B) | mm | 1160 | 1510 | 1500 | 1750 | 1650 | 1850 | 1850 | 2200 | 2400 | 2000 | |

| (H) | mm | 2550 | 2920 | 3500 | 3500 | 3600 | 3800 | 3840 | 4680 | 4800 | 5640 | |

| Motor power | kw | 7.5 | 15 | 30 | 30 | 30 | 37 | 37 | 55 | 55 | 55 | |

| Weight(Approx) | kg | 2280 | 3500 | 6000 | 6600 | 7500 | 9500 | 12500 | 16000 | 22000 | 23000 | |

Remarks: Final specifications are subject to contract or agreement.