How To Choose Hydraulic Press Machine Automation Line?Update:2021-10-27 Hits:409

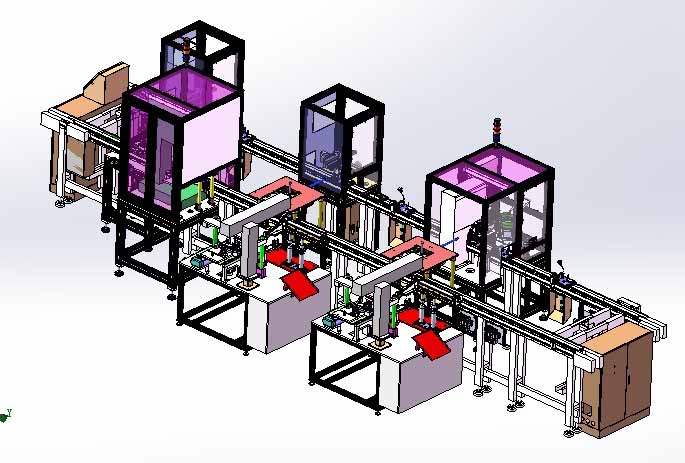

The hydraulic press machine automation line mainly consists of multi-station hydraulic presses. Because of their characteristics, they are used to produce different automotive sheet metal parts. With their unique advantages, they play a huge role in automotive automation and high-efficiency production systems.With the rapid development of the automobile industry, the four major process hydraulic industries for vehicle manufacturing have also flourished. In order to adapt to the ever-increasing output, various automated production lines came into being, and were given different production methods according to the characteristic requirements of individual products. Weifang enterprises choose different production methods according to their own product characteristics, analyze the common automatic production lines of hydraulic presses, and briefly analyze the characteristics and selection methods of the production lines.

The selection factors of hydraulic press machine automation line generally consider the following factors to select the type of hydraulic press machine automation line.

2. Material thickness: The tonnage of the hydraulic machine tool and the supporting form of the feeding mechanism should be selected in conjunction with the material.

3. Monthly supply and demand: Evaluate the production capacity, determine the production cycle, and weigh the types of automatic lines.

4. Hydraulic product volume and modeling difficulty: through modeling complexity and product quality requirements standards, comprehensive consideration of mold design methods and corresponding stamping automated production methods.

News

- Hot Stamping Hydraulic Press System2025-04-07

- Happy New Year 20252024-12-31

- Hydraulic Press for Automotive Engine Heat Shield2024-11-28

- Hydraulic Press Machine for Energy Storage Cold Plate2024-08-21