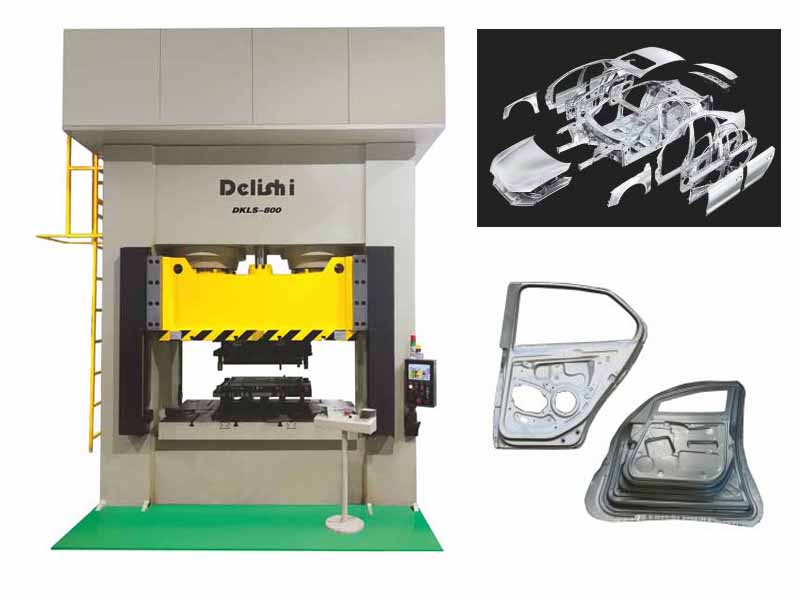

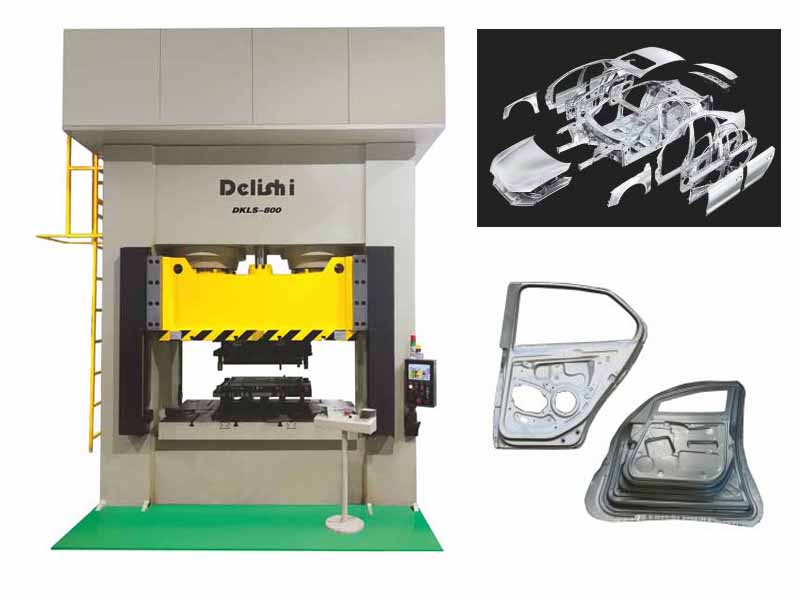

Hydraulic Press for Automobile Door Liner Press Forming

2023-04-25 16:13:00

Auto door lining is an important part of the car, and its processing generally requires the use of hydraulic presses for pressing and forming. This hydraulic press feeds pigs with a three-beam and four-column structure or a frame structure. It is specially used for stretching and forming of automobile door linings, and can also be used for stretching and pressing of various metal materials.

Under the working conditions of high pressure, high speed and large flow, the hydraulic system of hydraulic press for automobile foor liner press forming adopts the dynamic characteristics of advanced cartridge valve and electro-hydraulic proportional control valve, so that it can better meet the excellent control performance of hydraulic press , rapidity and stability indicators. Furthermore, the stamping and forming of the automobile door lining is carried out. The shear stamping equipment integrates shearing and stamping operations, which can significantly improve the forming efficiency of the automobile door lining.

Automobile door lining stretch forming process

Uncoiling shearing—(blanking)—tailor welding—drawing—shaping—trimming, punching, separation—oblique punching, etc. A variety of hydraulic press equipment and molds are required for punching, blanking, trimming, shaping, pressing, and stretching throughout the process engineering. The processing of automobile door lining generally includes processes such as drawing, trimming and punching, flanging, and shaping, and each process corresponds to the corresponding hydraulic press and mold for automobile door lining stretching and forming. The drawing process is the main forming process. Through the drawing process, the main shape of the part is basically formed.

According to the material, specification, thickness, process, etc. of the automobile door lining, it can produce 315 tons, 400 tons, 500 tons, 630 tons, 800 tons, 1000 tons and other hydraulic presses for stretching and forming automobile door linings. Customization is required. The whole machine has a compact structure and adopts advanced high-quality hydraulic electronic components, so it has a series of advantages such as sensitive and reliable action, safe and convenient operation, stable work, low energy consumption, long service life and durability.

Under the working conditions of high pressure, high speed and large flow, the hydraulic system of hydraulic press for automobile foor liner press forming adopts the dynamic characteristics of advanced cartridge valve and electro-hydraulic proportional control valve, so that it can better meet the excellent control performance of hydraulic press , rapidity and stability indicators. Furthermore, the stamping and forming of the automobile door lining is carried out. The shear stamping equipment integrates shearing and stamping operations, which can significantly improve the forming efficiency of the automobile door lining.

Automobile door lining stretch forming process

Uncoiling shearing—(blanking)—tailor welding—drawing—shaping—trimming, punching, separation—oblique punching, etc. A variety of hydraulic press equipment and molds are required for punching, blanking, trimming, shaping, pressing, and stretching throughout the process engineering. The processing of automobile door lining generally includes processes such as drawing, trimming and punching, flanging, and shaping, and each process corresponds to the corresponding hydraulic press and mold for automobile door lining stretching and forming. The drawing process is the main forming process. Through the drawing process, the main shape of the part is basically formed.

According to the material, specification, thickness, process, etc. of the automobile door lining, it can produce 315 tons, 400 tons, 500 tons, 630 tons, 800 tons, 1000 tons and other hydraulic presses for stretching and forming automobile door linings. Customization is required. The whole machine has a compact structure and adopts advanced high-quality hydraulic electronic components, so it has a series of advantages such as sensitive and reliable action, safe and convenient operation, stable work, low energy consumption, long service life and durability.

TOP

TOP WINDOWS

WINDOWS