Hydraulic Cold Extrusion Press Machine for Copper Heat Sink

2023-08-07 16:06:13

Hydraulic Cold Extrusion Press Machine for Copper Heat Sink – The Ultimate Solution for Your Manufacturing Needs

The manufacturing industry has come a long way since its inception. With each passing day, new technologies emerge with an aim to ease the production process, save time, and increase efficiency. One of the latest technologies that have been gaining momentum in the industry is the hydraulic cold extrusion press machine. This machine is the ultimate solution for copper heat sink manufacturing and is quickly becoming the go-to option for companies that want to optimize their production line.

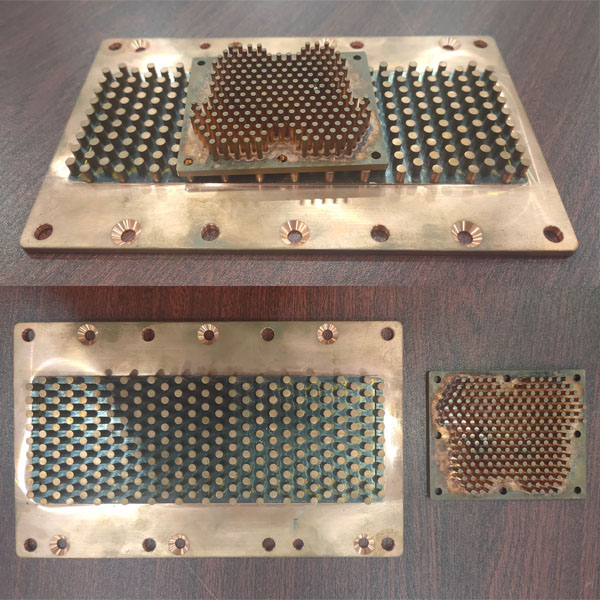

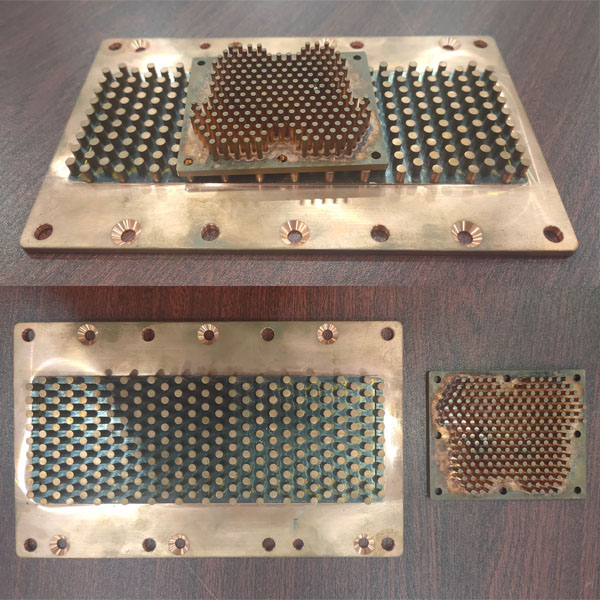

Hydraulic cold extrusion press machine works on the principle of using hydraulic pressure to compress a metal or alloy at ambient temperatures to a desired shape. These machines are designed to produce high-quality copper heat sinks, which are in high demand in the market. The copper heat sink is used to transfer heat from high-power devices to the ambient environment through conduction and radiation. It is widely used in electronic devices such as computers, televisions, and various other electrical appliances.

This machine is different from traditional hot extrusion machines, which require heating the metal before the extrusion process takes place. The hydraulic cold extrusion press machine is preferred to the hot extrusion machine because it reduces the risk of metal oxidation, maintains metallurgical integrity and promotes efficient heat dissipation, leading to the production of high-quality copper heat sinks.

Hydraulic cold extrusion press machines are designed with precision and are equipped with advanced features that make them stand out from the rest. They come in different models, with varying specifications that are tailor-made to meet specific production needs. These machines are easy to operate, and the production process is highly automated, which ensures higher efficiency, accuracy, and speed.

The hydraulic cold extrusion press machine works by using a hydraulic system that comprises of a motor, a pump, a pressure regulator, and a press. The pump delivers oil into the cylinder, thus creating pressure, which is then transferred to the press. The pressure applied to the press forces the metal through a die, creating the desired shape of the copper heat sink. The machine can produce different shapes and sizes of copper heat sinks by changing dies and adjusting the pressure.

The hydraulic cold extrusion press machine comes with numerous advantages that make it the ultimate solution for copper heat sink manufacturing. Firstly, it is an eco-friendly option as the process does not require heating, minimizing the need for energy and reducing carbon emissions. Secondly, it produces high-quality copper heat sinks that have excellent thermal conductivity properties, making them an efficient heat dissipation solution.

Thirdly, the machine is highly efficient, fast, and accurate, which helps to increase production, thus keeping up with the demand for copper heat sinks in the market. Fourthly, the machine is equipped with a safety system that ensures the operator's safety while the machine is in operation. Fifthly, the machine is easy to operate and requires minimal maintenance, which saves on time and resources.

In conclusion, the hydraulic cold extrusion press machine is the ultimate solution for copper heat sink manufacturing. It is an innovative technology that has revolutionized the manufacturing industry. The machine produces high-quality copper heat sinks that are efficient and reliable. It is also an eco-friendly and efficient solution that helps to increase production while reducing carbon emissions. Therefore, if you are looking to optimize your production line and produce high-quality copper heat sinks, the hydraulic cold extrusion press machine is the way to go.

The manufacturing industry has come a long way since its inception. With each passing day, new technologies emerge with an aim to ease the production process, save time, and increase efficiency. One of the latest technologies that have been gaining momentum in the industry is the hydraulic cold extrusion press machine. This machine is the ultimate solution for copper heat sink manufacturing and is quickly becoming the go-to option for companies that want to optimize their production line.

Hydraulic cold extrusion press machine works on the principle of using hydraulic pressure to compress a metal or alloy at ambient temperatures to a desired shape. These machines are designed to produce high-quality copper heat sinks, which are in high demand in the market. The copper heat sink is used to transfer heat from high-power devices to the ambient environment through conduction and radiation. It is widely used in electronic devices such as computers, televisions, and various other electrical appliances.

This machine is different from traditional hot extrusion machines, which require heating the metal before the extrusion process takes place. The hydraulic cold extrusion press machine is preferred to the hot extrusion machine because it reduces the risk of metal oxidation, maintains metallurgical integrity and promotes efficient heat dissipation, leading to the production of high-quality copper heat sinks.

Hydraulic cold extrusion press machines are designed with precision and are equipped with advanced features that make them stand out from the rest. They come in different models, with varying specifications that are tailor-made to meet specific production needs. These machines are easy to operate, and the production process is highly automated, which ensures higher efficiency, accuracy, and speed.

The hydraulic cold extrusion press machine works by using a hydraulic system that comprises of a motor, a pump, a pressure regulator, and a press. The pump delivers oil into the cylinder, thus creating pressure, which is then transferred to the press. The pressure applied to the press forces the metal through a die, creating the desired shape of the copper heat sink. The machine can produce different shapes and sizes of copper heat sinks by changing dies and adjusting the pressure.

The hydraulic cold extrusion press machine comes with numerous advantages that make it the ultimate solution for copper heat sink manufacturing. Firstly, it is an eco-friendly option as the process does not require heating, minimizing the need for energy and reducing carbon emissions. Secondly, it produces high-quality copper heat sinks that have excellent thermal conductivity properties, making them an efficient heat dissipation solution.

Thirdly, the machine is highly efficient, fast, and accurate, which helps to increase production, thus keeping up with the demand for copper heat sinks in the market. Fourthly, the machine is equipped with a safety system that ensures the operator's safety while the machine is in operation. Fifthly, the machine is easy to operate and requires minimal maintenance, which saves on time and resources.

In conclusion, the hydraulic cold extrusion press machine is the ultimate solution for copper heat sink manufacturing. It is an innovative technology that has revolutionized the manufacturing industry. The machine produces high-quality copper heat sinks that are efficient and reliable. It is also an eco-friendly and efficient solution that helps to increase production while reducing carbon emissions. Therefore, if you are looking to optimize your production line and produce high-quality copper heat sinks, the hydraulic cold extrusion press machine is the way to go.

TOP

TOP WINDOWS

WINDOWS