Deep Drawing Process Machine

2022-03-31 15:19:49

The drawing process is a process of processing the blank into an open hollow part by means of a die. This is a cold stamping process. The metal part drawing hydraulic press can process and draw cylindrical, doorway, spherical, conical, rectangular and other shapes. Various irregular opening hollow parts. By cooperating with other stamping processes, products with complex shapes can be produced. The metal parts stretching hydraulic press can adjust the working pressure, pressing speed, and stroke range. There are two processes: constant pressure and fixed stroke. It can maintain pressure delay and automatically return. The ejector in the middle of the table can also be used as a hydraulic pad.

As one of the main stamping processes, the stretching process of the metal parts stretching hydraulic press has a wide range of applications. This equipment is used for the stretching and forming of products, including stretching, re-stretching, reverse stretching and thinning. Stretching, etc.

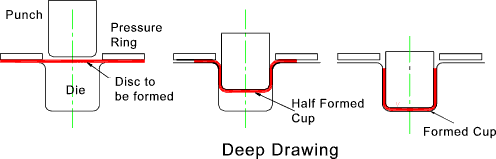

Drawing processing: The plate is drawn into the cavity of the concave mold with the help of the pressing force of the platen device and the punch, making it a container with a bottom. The processing in which the sidewall of the container is parallel to the stretching direction belongs to pure stretching processing; while the stretching processing for conical (or pyramidal) containers, hemispherical containers and parabolic containers, etc., includes expansion processing.

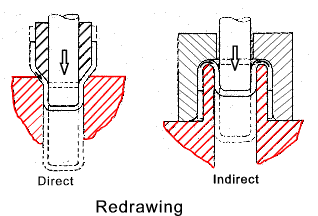

Reverse drawing processing: reverse drawing of the stretched workpiece, the inner side of the workpiece becomes the outer side, and its outer diameter becomes smaller.

normal four column deep drawing press servo four column deep drawing press frame servo deep drawing press

Thinning and drawing processing: Extrude the already formed container into a cavity of a concave mold slightly smaller than the outer diameter of the container with the help of a punch. Make it smaller in outer diameter and thinner in wall thickness. This both eliminates wall thickness deviations and smoothes the surface of the container.

TOP

TOP WINDOWS

WINDOWS