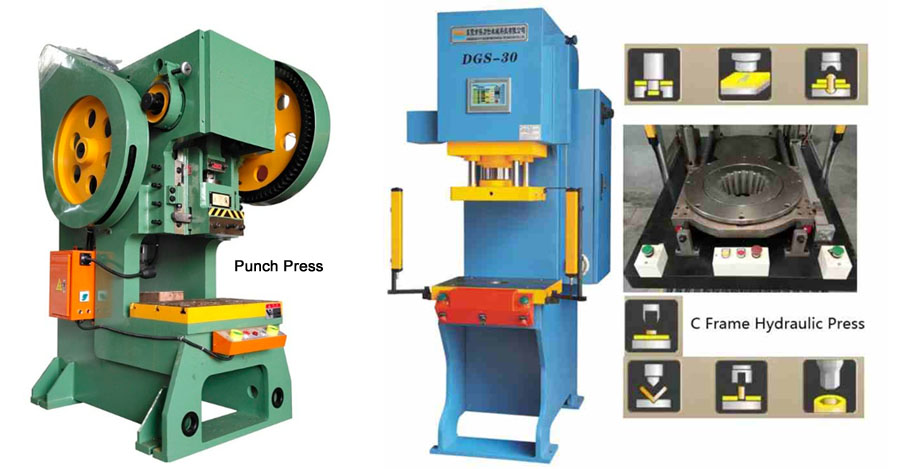

Difference Between Punch Press and Hydraulic Press

2022-08-01 15:47:49

Punch presses are also called open tilting presses and are also a branch of hydraulic presses. However, there are also certain differences between hydraulic presses and punch presses. Hydraulic presses are also called presses or hydraulic presses, which mainly use hydraulic oil medium, hydraulic cylinders and electrical systems to cooperate with each other through certain molds to press products. The following is an explanation of the difference between a hydraulic press and a punch.

In modern machining, the productivity requirements are low, and the blanking of small and medium-sized parts is generally carried out by hydraulic presses, and the production cycle is generally not more than half an hour. According to the size of the workpiece to be processed, the pressure load (centering or eccentric) and the forming method, the structure of the press is determined as a single-column hydraulic press with a C-shaped frame, a double-column or a four-column hydraulic press, and its body structure must be stable and can withstand the blanking time. shock vibration caused. Hydraulic press stretching refers to the process of positioning the blanking parts in the mold, and when the hydraulic press performs stretching and forging, the blank holder controls the flow of metal to form a cavity workpiece. Generally speaking, deep drawing refers to a workpiece whose depth of drawn portion or recessed portion is more than half of its diameter.

Second, the punch features detailed description

Punch blanking is to cut, shear and punch the plate to make it into the required shape. The material of the kneader can be a single sheet or a continuous long strip. Stamping can blank, but also includes forming, bending, flanging, punching and other processes. The punch press is based on the blanking and the above-mentioned forging and stretching process, and the punch press can be called a hydraulic press.

Generally speaking, the punch press has simple structure, fast production rhythm and high efficiency, and is suitable for large-scale and relatively simple blanking forming processing. The hydraulic press is suitable for small and medium batch production, which requires precision and depth, the shape is changeable, and the speed, pressure and position of the slider are more precise, and the production process is processed according to the order.

TOP

TOP WINDOWS

WINDOWS