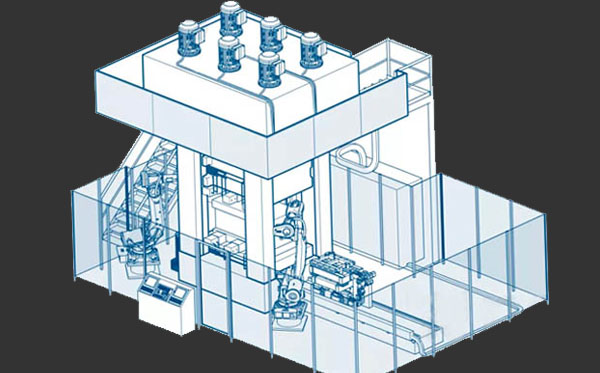

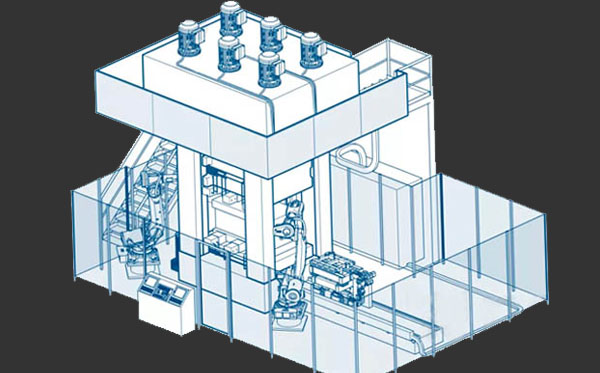

Fully-Automatic Hydraulic Press Advantages

2024-11-11 09:18:56

Fully-automatic hydraulic press is a kind of equipment that uses liquid pressure to transfer energy and realize various pressure processing processes. It can automatically complete operations such as stamping, forming, extrusion and other operations under the preset program control, and is widely used in many industrial fields such as metal processing, plastic molding, powder metallurgy, etc. With the continuous progress of science and technology, fully-automatic hydraulic press has entered the era of intelligent upgrading and has become a new trend of industrial production.

Data-based monitoring and analysis

The intelligent upgrade of the fully automatic hydraulic press includes a data acquisition and monitoring system, which can obtain and record key parameters such as pressure, temperature and working speed in real time. By analyzing this data, potential problems can be identified and predictive maintenance can be carried out to improve the reliability and efficiency of the equipment.

Remote monitoring and operation

The intelligent upgrade of the fully automatic hydraulic press also includes remote monitoring and operation functions, so that operators can remotely monitor the status and operation of the equipment through the Internet, and even remotely operate and adjust the parameters. This enables remote fault diagnosis and rapid response, reducing downtime and increasing productivity.

Self-learning and optimization

Intelligent hydraulic presses can also continuously learn and optimize process parameters through machine learning and artificial intelligence techniques. By analyzing historical data and real-time feedback, the intelligent hydraulic press can automatically adjust parameters and processes to achieve higher production efficiency and quality.

Human-machine collaboration and safety

Intelligent hydraulic presses can achieve a higher degree of human-machine collaboration, providing a more intuitive and friendly operation interface through human-machine interface and artificial intelligence algorithms, reducing the risk of misoperation. At the same time, intelligent hydraulic presses can also achieve higher safety through sensors and monitoring systems, and detect and prevent potentially dangerous situations in time.

Energy saving and environmental protection

Intelligent hydraulic presses can achieve higher energy efficiency and environmental performance by optimizing process parameters and reducing energy waste and waste generation. This not only helps to reduce production costs, but also meets the requirements of sustainability.

The intelligent upgrade of Delishi/Goodsjack fully-automatic hydraulic hydraulic press will promote the development of industrial production. It improves production efficiency, quality and safety through the characteristics and advantages of data monitoring and analysis, remote monitoring and operation, self-learning and optimization, human-machine collaboration and safety, and energy conservation and environmental protection, and brings greater competitive advantages to enterprises.

Data-based monitoring and analysis

The intelligent upgrade of the fully automatic hydraulic press includes a data acquisition and monitoring system, which can obtain and record key parameters such as pressure, temperature and working speed in real time. By analyzing this data, potential problems can be identified and predictive maintenance can be carried out to improve the reliability and efficiency of the equipment.

Remote monitoring and operation

The intelligent upgrade of the fully automatic hydraulic press also includes remote monitoring and operation functions, so that operators can remotely monitor the status and operation of the equipment through the Internet, and even remotely operate and adjust the parameters. This enables remote fault diagnosis and rapid response, reducing downtime and increasing productivity.

Self-learning and optimization

Intelligent hydraulic presses can also continuously learn and optimize process parameters through machine learning and artificial intelligence techniques. By analyzing historical data and real-time feedback, the intelligent hydraulic press can automatically adjust parameters and processes to achieve higher production efficiency and quality.

Human-machine collaboration and safety

Intelligent hydraulic presses can achieve a higher degree of human-machine collaboration, providing a more intuitive and friendly operation interface through human-machine interface and artificial intelligence algorithms, reducing the risk of misoperation. At the same time, intelligent hydraulic presses can also achieve higher safety through sensors and monitoring systems, and detect and prevent potentially dangerous situations in time.

Energy saving and environmental protection

Intelligent hydraulic presses can achieve higher energy efficiency and environmental performance by optimizing process parameters and reducing energy waste and waste generation. This not only helps to reduce production costs, but also meets the requirements of sustainability.

The intelligent upgrade of Delishi/Goodsjack fully-automatic hydraulic hydraulic press will promote the development of industrial production. It improves production efficiency, quality and safety through the characteristics and advantages of data monitoring and analysis, remote monitoring and operation, self-learning and optimization, human-machine collaboration and safety, and energy conservation and environmental protection, and brings greater competitive advantages to enterprises.

TOP

TOP WINDOWS

WINDOWS