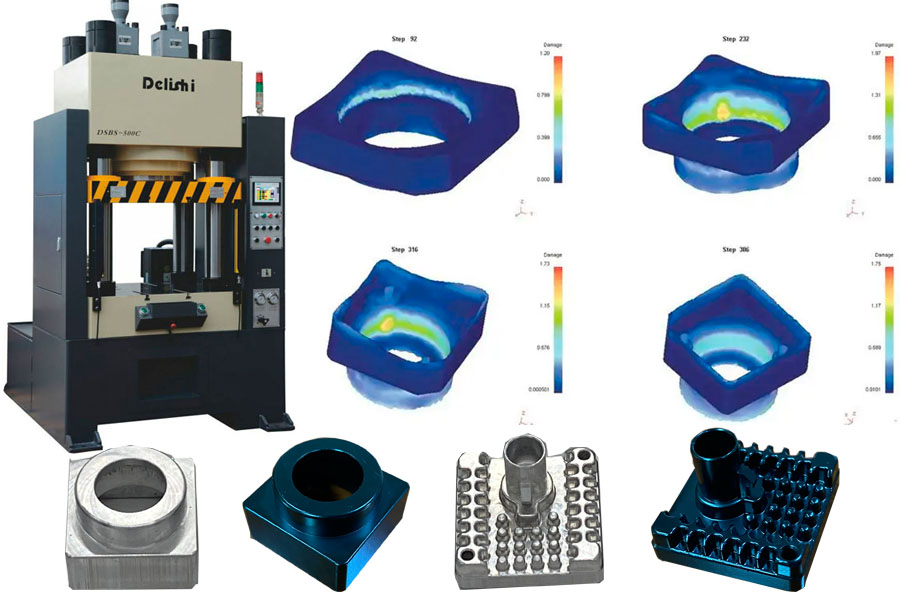

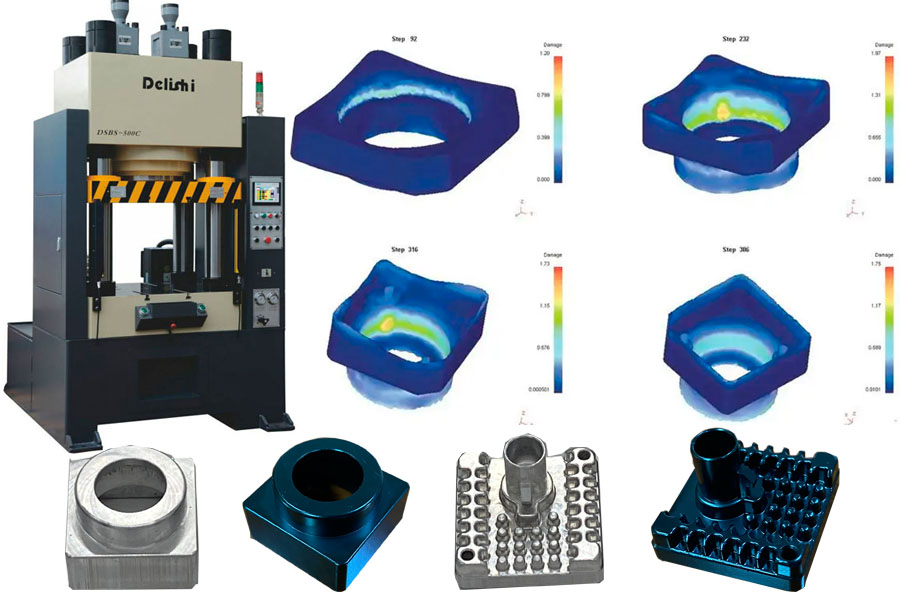

Hydraulic Cold Forging Press for Car Camera

2024-09-18 15:49:28

Goodsjack/Delishi hydraulic cold forging press is suitable for cold extrusion molding, stamping, shallow drawing and shaping of metal or non-metal, front and rear covers of car cameras, car camera housings, precision camera aluminum housings and other products.

When the highly intelligent Tesla electric car came out, it set off a global sensation. With its excellent automatic safety driving function, it constantly refreshed our eyes. The "eyes" and "ears" of the automatic safety driving function are the cameras and radar probes around the car body. As the automatic safety driving function continues to be enriched, the whole car needs to detect the environment around the car body without blind spots. The number of various cameras and radar probes throughout the car body continues to increase.

Goodsjack/Delishi Hydraulic Machiney has been focusing on the hydraulic press solution industry for nearly 30 years. We have mature cold extrusion, high-speed hot forging, warm extrusion, stretching, and sheet metal forming technologies. Welcome to visit us! Gear warm extrusion, camera front and rear cover extrusion, bicycle seat integrated molding, photovoltaic inverter housing stretching and other processes are all independently developed and designed by our company. Our company has a full range of technical personnel and mold designers, and can provide one-stop solutions for hydraulic presses for mid-to-high-end manufacturing industries!

When the highly intelligent Tesla electric car came out, it set off a global sensation. With its excellent automatic safety driving function, it constantly refreshed our eyes. The "eyes" and "ears" of the automatic safety driving function are the cameras and radar probes around the car body. As the automatic safety driving function continues to be enriched, the whole car needs to detect the environment around the car body without blind spots. The number of various cameras and radar probes throughout the car body continues to increase.

Goodsjack/Delishi Hydraulic Machiney has been focusing on the hydraulic press solution industry for nearly 30 years. We have mature cold extrusion, high-speed hot forging, warm extrusion, stretching, and sheet metal forming technologies. Welcome to visit us! Gear warm extrusion, camera front and rear cover extrusion, bicycle seat integrated molding, photovoltaic inverter housing stretching and other processes are all independently developed and designed by our company. Our company has a full range of technical personnel and mold designers, and can provide one-stop solutions for hydraulic presses for mid-to-high-end manufacturing industries!

TOP

TOP WINDOWS

WINDOWS