How to Choose the Suitable Hydraulic Press Guard

2024-12-03 09:37:32

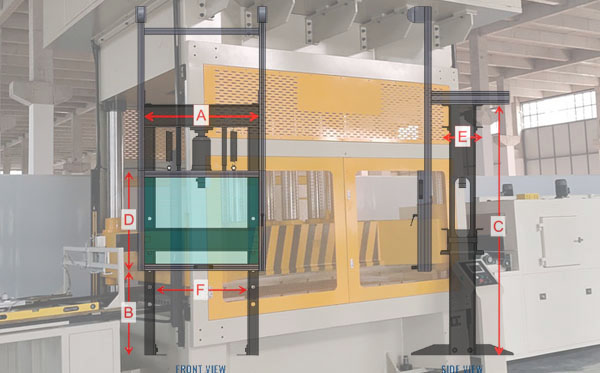

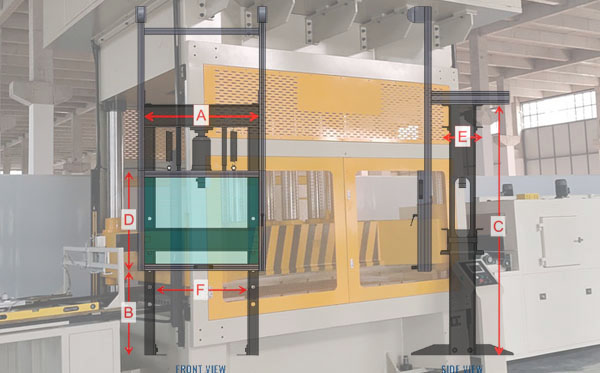

Goodsjack/Delish Hydraulic Presses are designed with protective structure, many guards for you choice.

In the working process of the hydraulic press, its moving beam plate and other components will carry out high-speed and high-pressure movement. For example, in the stamping hydraulic press, the moving beam plate is pressed down quickly with a large pressure, and if the operator's hands or other parts of the body accidentally enter the working area, it is easy to be pinched and crushed. Guards such as fences, doors, etc., can isolate the operator from dangerous moving parts and avoid direct contact with injuries.

Following are key points of about how to choose the suitable hydraulic press guard.

1. The type and working mode of the hydraulic press

Stamping hydraulic press: If it is a stamping hydraulic press, due to the rapid downward pressure of the moving beam plate in the working process and the large impact force, the photoelectric safety device is a better choice. Because it can quickly detect whether the operator's hand has entered the danger zone, stop the hydraulic press action in an instant, and prevent stamping accidents. For example, in the stamping workshop of auto parts, a large number of photoelectric protective devices are used to ensure the safety of operators.

Extrusion hydraulic press: For extrusion hydraulic press, the working process is relatively slow, but the pressure lasts for a long time, in this case, the combination of protective fence and protective door may be more suitable. The protective fence can prevent the operator from accidentally approaching the extrusion part during operation, and the interlocking device of the protective door can ensure that the hydraulic press cannot be started in the open state of the door, ensuring the safety during the operation of loading and unloading.

2. Work environment

Harsh environments (e.g. high temperatures, humidity, dust): In high temperature environments, some electronic components may be affected, where mechanical guards (e.g., handles, pendulum safety devices) are relatively more reliable because they are less affected by temperature. In humid and dusty environments, the performance of optoelectronic safety devices may be degraded, as dust may block light, or moisture may damage electronic components. At this time, it is necessary to choose a photoelectric device with a high protection level or consider other mechanical or controlled protection methods, and pay attention to the regular cleaning and maintenance of the protective device.

Space constraints: If space in the workplace is limited and a large fence may not be appropriate, a smaller safety barrier or a two-hand safety device may be an option. The safety light curtain can be flexibly installed around the hydraulic press without taking up too much space; Two-hand operated safety devices are usually mounted directly on the worktop and do not interfere too much with the surrounding space.

3. Frequency of operation and number of operators

High operating frequency: In the case of high operating frequency, the guards must not interfere too much with the operating process. For example, in a press shop for electronic components, where operations are frequent, it is appropriate to use a photoelectric safety device or a two-hand operated safety device that reacts quickly and does not hinder operation too much. The photoelectric safety device can react quickly when the operator's hand enters the dangerous area, and the two-hand operated safety device can also ensure safety while allowing skilled operators to work with high efficiency.

Multiple operators: If there are multiple operators working around the hydraulic press at the same time, safety light curtains or protective fences may be a better option. The safety light curtain can cover a large area and detect the movements of multiple operators at the same time; Protective barriers can divide the entire work area and prevent irrelevant people from entering the danger zone.

4. Safety and reliability requirements

High security requirements (e.g., military, aerospace): In military and aerospace and other fields with extremely high security requirements, a combination of multiple protective devices is often required. For example, in addition to the basic photoelectric safety device and guard door interlock, it is also equipped with a pressure sensor to monitor the hydraulic pressure in real time and prevent safety accidents caused by abnormal pressure. And these guards often need to undergo rigorous quality testing and certification to ensure their reliability.

General industrial production: For general industrial production, the selection of protective devices is based on a specific risk assessment. In the case of simple machining of small parts, a two-hand safety device or a simple protective fence may be sufficient for basic safety needs.

5. Cost and maintenance difficulty

Cost budget: The cost of different guards varies greatly. Mechanical guards (e.g., handles, swings) are usually less costly, while some high-precision optoelectronic safety devices or protective doors with complex interlocking functions are more costly. The cost budget of the business needs to be considered when choosing. If you have a limited budget, you can prioritize mechanical guards and combine them with basic safety operating procedures to ensure safety.

Difficulty of maintenance: The mechanical guard has a simple structure and is relatively easy to maintain, and generally only needs to check the wear and tear of mechanical parts regularly. Electronic protective devices such as photoelectric safety devices and capacitive safety devices require professional maintenance, including checking circuits and cleaning optical components. If you don't have a professional maintenance staff, you may need to choose a guard that is less difficult to maintain or consider the cost of external repair services.

In the working process of the hydraulic press, its moving beam plate and other components will carry out high-speed and high-pressure movement. For example, in the stamping hydraulic press, the moving beam plate is pressed down quickly with a large pressure, and if the operator's hands or other parts of the body accidentally enter the working area, it is easy to be pinched and crushed. Guards such as fences, doors, etc., can isolate the operator from dangerous moving parts and avoid direct contact with injuries.

Following are key points of about how to choose the suitable hydraulic press guard.

1. The type and working mode of the hydraulic press

Stamping hydraulic press: If it is a stamping hydraulic press, due to the rapid downward pressure of the moving beam plate in the working process and the large impact force, the photoelectric safety device is a better choice. Because it can quickly detect whether the operator's hand has entered the danger zone, stop the hydraulic press action in an instant, and prevent stamping accidents. For example, in the stamping workshop of auto parts, a large number of photoelectric protective devices are used to ensure the safety of operators.

Extrusion hydraulic press: For extrusion hydraulic press, the working process is relatively slow, but the pressure lasts for a long time, in this case, the combination of protective fence and protective door may be more suitable. The protective fence can prevent the operator from accidentally approaching the extrusion part during operation, and the interlocking device of the protective door can ensure that the hydraulic press cannot be started in the open state of the door, ensuring the safety during the operation of loading and unloading.

2. Work environment

Harsh environments (e.g. high temperatures, humidity, dust): In high temperature environments, some electronic components may be affected, where mechanical guards (e.g., handles, pendulum safety devices) are relatively more reliable because they are less affected by temperature. In humid and dusty environments, the performance of optoelectronic safety devices may be degraded, as dust may block light, or moisture may damage electronic components. At this time, it is necessary to choose a photoelectric device with a high protection level or consider other mechanical or controlled protection methods, and pay attention to the regular cleaning and maintenance of the protective device.

Space constraints: If space in the workplace is limited and a large fence may not be appropriate, a smaller safety barrier or a two-hand safety device may be an option. The safety light curtain can be flexibly installed around the hydraulic press without taking up too much space; Two-hand operated safety devices are usually mounted directly on the worktop and do not interfere too much with the surrounding space.

3. Frequency of operation and number of operators

High operating frequency: In the case of high operating frequency, the guards must not interfere too much with the operating process. For example, in a press shop for electronic components, where operations are frequent, it is appropriate to use a photoelectric safety device or a two-hand operated safety device that reacts quickly and does not hinder operation too much. The photoelectric safety device can react quickly when the operator's hand enters the dangerous area, and the two-hand operated safety device can also ensure safety while allowing skilled operators to work with high efficiency.

Multiple operators: If there are multiple operators working around the hydraulic press at the same time, safety light curtains or protective fences may be a better option. The safety light curtain can cover a large area and detect the movements of multiple operators at the same time; Protective barriers can divide the entire work area and prevent irrelevant people from entering the danger zone.

4. Safety and reliability requirements

High security requirements (e.g., military, aerospace): In military and aerospace and other fields with extremely high security requirements, a combination of multiple protective devices is often required. For example, in addition to the basic photoelectric safety device and guard door interlock, it is also equipped with a pressure sensor to monitor the hydraulic pressure in real time and prevent safety accidents caused by abnormal pressure. And these guards often need to undergo rigorous quality testing and certification to ensure their reliability.

General industrial production: For general industrial production, the selection of protective devices is based on a specific risk assessment. In the case of simple machining of small parts, a two-hand safety device or a simple protective fence may be sufficient for basic safety needs.

5. Cost and maintenance difficulty

Cost budget: The cost of different guards varies greatly. Mechanical guards (e.g., handles, swings) are usually less costly, while some high-precision optoelectronic safety devices or protective doors with complex interlocking functions are more costly. The cost budget of the business needs to be considered when choosing. If you have a limited budget, you can prioritize mechanical guards and combine them with basic safety operating procedures to ensure safety.

Difficulty of maintenance: The mechanical guard has a simple structure and is relatively easy to maintain, and generally only needs to check the wear and tear of mechanical parts regularly. Electronic protective devices such as photoelectric safety devices and capacitive safety devices require professional maintenance, including checking circuits and cleaning optical components. If you don't have a professional maintenance staff, you may need to choose a guard that is less difficult to maintain or consider the cost of external repair services.

TOP

TOP WINDOWS

WINDOWS