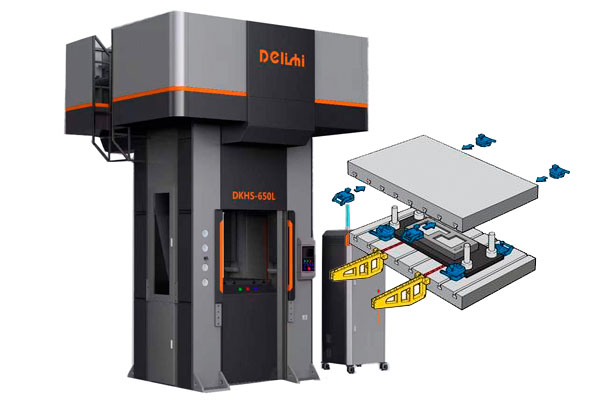

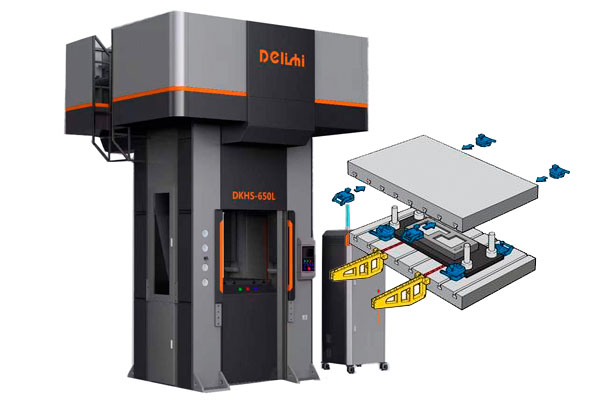

Hydraulic Press with Double-Station Quick Die Change

2024-11-22 15:38:51

Hydraulic Press with Double-Station Quick Die Change refers to a hydraulic press equipped with a system that allows for rapid switching between two different sets of dies (or molds) simultaneously, typically achieved through a dedicated die cart with two separate stations where one die set is pre-positioned while the other is actively being used on the press, significantly reducing downtime during die changeovers.

Following are brief introduce of hydraulic press with double-station quick die change.

Structural design

Dual-station bench: It has two stations, which can be operated simultaneously or alternately to improve production efficiency. For example, in the production of automotive parts, one station is for stamping and forming, and the other station can simultaneously change or prepare molds.

Mobile workbench: It is usually equipped with high-precision linear guides and drive devices to achieve fast and smooth movement of the workbench. For example, ball screw drive or gear rack drive is used to ensure accurate mold replacement.

Hydraulic system: It provides powerful power and pushes the slider through the cylinder for stamping, forming and other operations. Advanced hydraulic control technology is used to achieve precise adjustment of pressure and speed.

Working principle

Mold replacement: When the mold needs to be replaced, the slider of the hydraulic press rises to the specified position, the mobile workbench moves out, and the workbench with the old mold is moved to the mold change area. At the same time, the workbench where the prepared new mold is located is moved to the working position, and then the slider descends to debug and produce the new mold.

Hydraulic drive: The hydraulic pump sucks the hydraulic oil out of the oil tank, and delivers the high-pressure oil to different chambers of the oil cylinder through control components such as the reversing valve, pushing the piston to move, thereby realizing the up and down movement of the slider.

Advantages

Improve production efficiency: The double-station design and fast mold change function greatly reduce the mold replacement time, increase the effective working time of the equipment, and increase production output.

Reduce labor intensity: The high degree of automation reduces the workload of manual mold handling and adjustment, and reduces the labor intensity of operators.

Improve product quality: Accurate mold positioning and stable hydraulic system ensure product dimensional accuracy and quality stability.

Application areas

Automobile manufacturing: used for stamping and forming processing of automobile body parts, engine parts, etc.

Electronic equipment production: stamping production of parts such as shells and buttons of electronic products such as mobile phones and computers.

Home appliance manufacturing: processing of shells and parts of home appliances such as refrigerators, air conditioners, and washing machines.

Goodsjack/Delishi Hydraulic Machinery is a professional R & D hydraulic press solution manufacturer with nearly 30 years industry experiences. If you need hydraulic press with double-station quick die change, please contact us, once get your specifical requirements, then best hydraulic press offer will be provided for you.

Following are brief introduce of hydraulic press with double-station quick die change.

Structural design

Dual-station bench: It has two stations, which can be operated simultaneously or alternately to improve production efficiency. For example, in the production of automotive parts, one station is for stamping and forming, and the other station can simultaneously change or prepare molds.

Mobile workbench: It is usually equipped with high-precision linear guides and drive devices to achieve fast and smooth movement of the workbench. For example, ball screw drive or gear rack drive is used to ensure accurate mold replacement.

Hydraulic system: It provides powerful power and pushes the slider through the cylinder for stamping, forming and other operations. Advanced hydraulic control technology is used to achieve precise adjustment of pressure and speed.

Working principle

Mold replacement: When the mold needs to be replaced, the slider of the hydraulic press rises to the specified position, the mobile workbench moves out, and the workbench with the old mold is moved to the mold change area. At the same time, the workbench where the prepared new mold is located is moved to the working position, and then the slider descends to debug and produce the new mold.

Hydraulic drive: The hydraulic pump sucks the hydraulic oil out of the oil tank, and delivers the high-pressure oil to different chambers of the oil cylinder through control components such as the reversing valve, pushing the piston to move, thereby realizing the up and down movement of the slider.

Advantages

Improve production efficiency: The double-station design and fast mold change function greatly reduce the mold replacement time, increase the effective working time of the equipment, and increase production output.

Reduce labor intensity: The high degree of automation reduces the workload of manual mold handling and adjustment, and reduces the labor intensity of operators.

Improve product quality: Accurate mold positioning and stable hydraulic system ensure product dimensional accuracy and quality stability.

Application areas

Automobile manufacturing: used for stamping and forming processing of automobile body parts, engine parts, etc.

Electronic equipment production: stamping production of parts such as shells and buttons of electronic products such as mobile phones and computers.

Home appliance manufacturing: processing of shells and parts of home appliances such as refrigerators, air conditioners, and washing machines.

Goodsjack/Delishi Hydraulic Machinery is a professional R & D hydraulic press solution manufacturer with nearly 30 years industry experiences. If you need hydraulic press with double-station quick die change, please contact us, once get your specifical requirements, then best hydraulic press offer will be provided for you.

TOP

TOP WINDOWS

WINDOWS