What is the Method of Cavity Cold Extrusion Press

2024-06-25 11:00:50

What is the Method of Cavity Cold Extrusion Press?

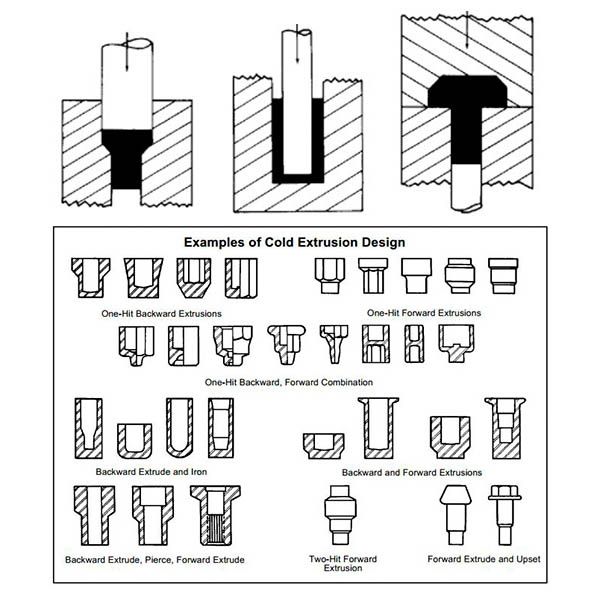

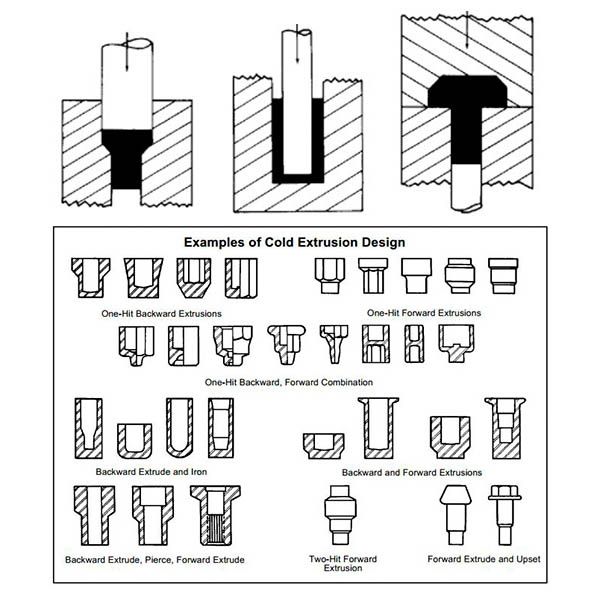

A cold extrusion hydraulic press is a kind of equipment that implements the extrusion molding process. Mainly used for extruding and forging metal materials, such as upsetting, drawing, drilling, bending, stamping, plastics, etc.

1. Selection of cold extrusion press machine

Cavity cold extrusion press generally uses a hydraulic press machine. The requirements for the hydraulic press machine are: good rigidity, accurate piston guide, and stable and reliable operation. At the same time, there must be a safety protection device to prevent the extrusion punch from breaking or the billet from being squeezed and splashing out to injure people.

2. Design and manufacture of extrusion punches

The size calculation method of the cold extrusion punch is as follows: Its processing technology is: billet preparation → design and manufacture of punches → billet and punch surface treatment → die loading → extrusion → die unloading → inspection.

○ Copper and zinc are plated on the surface of the punch. During extrusion, aluminum disulfide or kerosene can be diluted for lubrication.

○ Add 20% dilute sulfuric acid to copper sulfate aqueous solution and apply it to the punch after gasoline cleaning.

○ After the punch is phosphated, the surface is coated with molybdenum disulfide to increase the number of times the punch can be used.

The cold extrusion hydraulic press produced by Goodsjack/Delishi Hydraulic Machinery is a vertical extrusion equipment that uses high-pressure liquid as the power source. The maximum working pressure of the master cylinder liquid can be maintained at 25MPa. It has the characteristics of high dimensional accuracy, high material utilization, high production efficiency, and high product strength. Users can customize the frame or four-column (cold/hot) extrusion equipment according to their needs.

A cold extrusion hydraulic press is a kind of equipment that implements the extrusion molding process. Mainly used for extruding and forging metal materials, such as upsetting, drawing, drilling, bending, stamping, plastics, etc.

1. Selection of cold extrusion press machine

Cavity cold extrusion press generally uses a hydraulic press machine. The requirements for the hydraulic press machine are: good rigidity, accurate piston guide, and stable and reliable operation. At the same time, there must be a safety protection device to prevent the extrusion punch from breaking or the billet from being squeezed and splashing out to injure people.

2. Design and manufacture of extrusion punches

The size calculation method of the cold extrusion punch is as follows: Its processing technology is: billet preparation → design and manufacture of punches → billet and punch surface treatment → die loading → extrusion → die unloading → inspection.

3. Lubrication of cold extrusion

During the cold extrusion process, the punch and the billet should be lubricated to reduce the extrusion force, increase the service life of the punch and reduce the damage of the billet. The method is:○ Copper and zinc are plated on the surface of the punch. During extrusion, aluminum disulfide or kerosene can be diluted for lubrication.

○ Add 20% dilute sulfuric acid to copper sulfate aqueous solution and apply it to the punch after gasoline cleaning.

○ After the punch is phosphated, the surface is coated with molybdenum disulfide to increase the number of times the punch can be used.

The cold extrusion hydraulic press produced by Goodsjack/Delishi Hydraulic Machinery is a vertical extrusion equipment that uses high-pressure liquid as the power source. The maximum working pressure of the master cylinder liquid can be maintained at 25MPa. It has the characteristics of high dimensional accuracy, high material utilization, high production efficiency, and high product strength. Users can customize the frame or four-column (cold/hot) extrusion equipment according to their needs.

TOP

TOP WINDOWS

WINDOWS