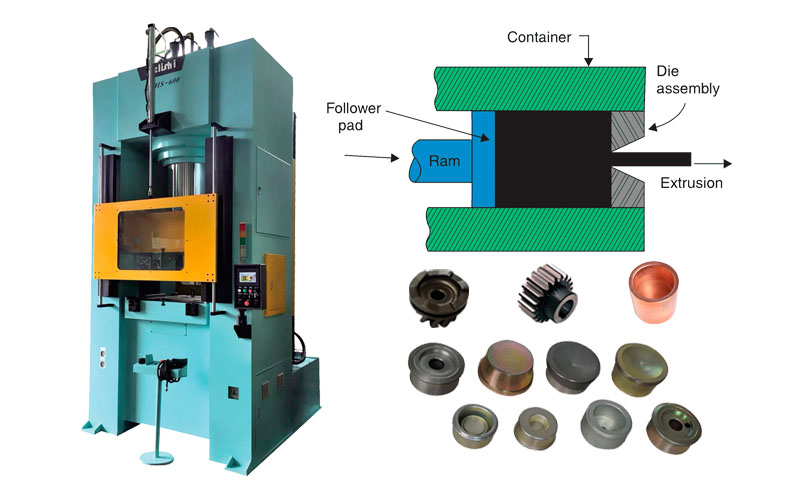

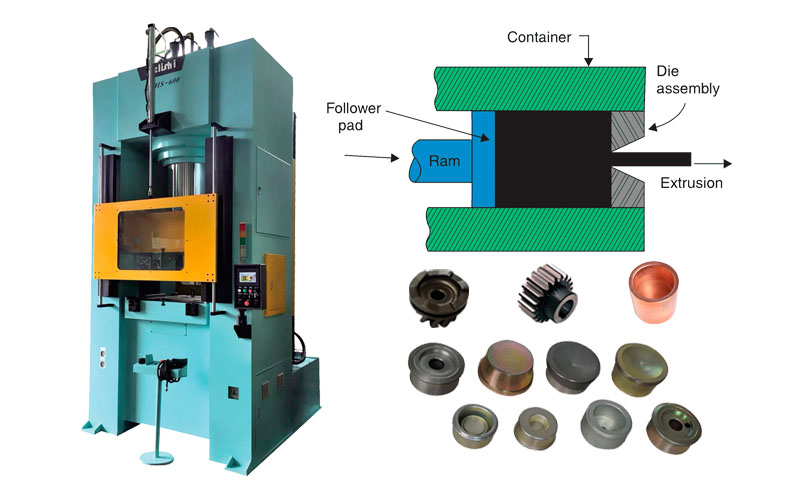

What Problems Will Occur in Processing of Cold Extrusion Press

2024-10-07 16:59:19

During the processing of cold extrusion press, the following problems may occur:

1. the mold problem

Mold wear: Due to the large friction between the metal blank and the die during cold extrusion, it is easy to cause die wear. Mold wear will affect the dimensional accuracy and surface quality of parts, reducing the service life of the mold.

Mold rupture: During the cold extrusion process, the mold is subjected to tremendous pressure, and if the mold is not strong enough or the design is not reasonable, it is easy to rupture. A cracked mold will not only damage the equipment, but also affect the production schedule.

Elastic deformation of the mold: When the mold is subjected to greater pressure, elastic deformation may occur. The elastic deformation of the mold will lead to a decrease in the dimensional accuracy of the part, which will affect the product quality.

2. the quality of parts

Surface quality problems: The surface of cold-extruded parts may have defects such as scratches, cracks, pitting, etc. These surface quality problems can be caused by a rough surface of the mold, an unclean surface of the blank, or poor lubrication during the extrusion process.

Dimensional accuracy issues: The dimensional accuracy of cold extruded parts can be affected by factors such as die wear, blank size changes, and unstable extrusion pressure. Dimensional accuracy issues can cause parts to fail to meet design requirements, affecting the assembly and performance of the product.

Internal structure problems: During the cold extrusion process, the internal structure of the metal material may change, such as grain refinement, dislocation density increase, etc. If the internal structure changes unevenly, it may lead to a decrease in the mechanical properties of the part, cracks and other defects.

3. Hydraulic press problems

Insufficient pressure: Cold extrusion requires a large pressure, and if the pressure of the equipment is insufficient, the extrusion process cannot be completed. Insufficient pressure can be caused by equipment failure, leakage in the hydraulic system, or improper pressure regulation.

Equipment Vibration: During the cold extrusion process, the equipment may vibrate. Machine vibration can affect the dimensional accuracy and surface quality of parts, and may also damage the device. Machine vibration can be caused by an insecure installation of the equipment, an unbalanced mold, or excessive impact during the extrusion process.

4. Process problems

Poor lubrication: During cold extrusion, good lubrication can reduce the friction between the mold and the blank, reduce the wear of the mold, and improve the surface quality of the parts. If the lubrication is poor, it is easy to lead to problems such as increased mold wear and deterioration of the surface quality of parts.

Improper extrusion speed: too fast extrusion speed may lead to the deterioration of the surface quality of the part and the aggravation of mold wear; If the extrusion speed is too slow, the production efficiency will be reduced. Therefore, it is necessary to choose the appropriate extrusion speed according to the specific situation.

Missize of blank: Blank size that is too large or too small will affect the smooth progress of the cold extrusion process. Excessive size of the blank may cause the mold to crack; If the blank size is too small, it may result in a decrease in the dimensional accuracy of the part.

In order to avoid these problems, in the processing of cold extrusion press, it is necessary to select the appropriate die material and structure, optimize the extrusion process parameters, ensure the normal operation of the equipment, and strengthen the quality control of the production process.

1. the mold problem

Mold wear: Due to the large friction between the metal blank and the die during cold extrusion, it is easy to cause die wear. Mold wear will affect the dimensional accuracy and surface quality of parts, reducing the service life of the mold.

Mold rupture: During the cold extrusion process, the mold is subjected to tremendous pressure, and if the mold is not strong enough or the design is not reasonable, it is easy to rupture. A cracked mold will not only damage the equipment, but also affect the production schedule.

Elastic deformation of the mold: When the mold is subjected to greater pressure, elastic deformation may occur. The elastic deformation of the mold will lead to a decrease in the dimensional accuracy of the part, which will affect the product quality.

2. the quality of parts

Surface quality problems: The surface of cold-extruded parts may have defects such as scratches, cracks, pitting, etc. These surface quality problems can be caused by a rough surface of the mold, an unclean surface of the blank, or poor lubrication during the extrusion process.

Dimensional accuracy issues: The dimensional accuracy of cold extruded parts can be affected by factors such as die wear, blank size changes, and unstable extrusion pressure. Dimensional accuracy issues can cause parts to fail to meet design requirements, affecting the assembly and performance of the product.

Internal structure problems: During the cold extrusion process, the internal structure of the metal material may change, such as grain refinement, dislocation density increase, etc. If the internal structure changes unevenly, it may lead to a decrease in the mechanical properties of the part, cracks and other defects.

3. Hydraulic press problems

Insufficient pressure: Cold extrusion requires a large pressure, and if the pressure of the equipment is insufficient, the extrusion process cannot be completed. Insufficient pressure can be caused by equipment failure, leakage in the hydraulic system, or improper pressure regulation.

Equipment Vibration: During the cold extrusion process, the equipment may vibrate. Machine vibration can affect the dimensional accuracy and surface quality of parts, and may also damage the device. Machine vibration can be caused by an insecure installation of the equipment, an unbalanced mold, or excessive impact during the extrusion process.

4. Process problems

Poor lubrication: During cold extrusion, good lubrication can reduce the friction between the mold and the blank, reduce the wear of the mold, and improve the surface quality of the parts. If the lubrication is poor, it is easy to lead to problems such as increased mold wear and deterioration of the surface quality of parts.

Improper extrusion speed: too fast extrusion speed may lead to the deterioration of the surface quality of the part and the aggravation of mold wear; If the extrusion speed is too slow, the production efficiency will be reduced. Therefore, it is necessary to choose the appropriate extrusion speed according to the specific situation.

Missize of blank: Blank size that is too large or too small will affect the smooth progress of the cold extrusion process. Excessive size of the blank may cause the mold to crack; If the blank size is too small, it may result in a decrease in the dimensional accuracy of the part.

In order to avoid these problems, in the processing of cold extrusion press, it is necessary to select the appropriate die material and structure, optimize the extrusion process parameters, ensure the normal operation of the equipment, and strengthen the quality control of the production process.

TOP

TOP WINDOWS

WINDOWS