Use Range

This double action servo deep drawing press is three beams and four columns structure. Advanced two way cartridge valve system ensures high reliability and much less hydraulic shock direction change.The deep drawing press capacity range from 50 to 2000 tons.

Product Details

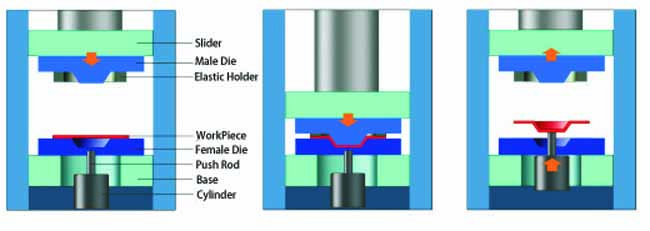

This double action servo deep drawing hydraulic press is three beams and four columns structure. Advanced two way cartridge valve system ensures high reliability and much less hydraulic shock direction change. Main hydraulic cylinder of deep drawing hydraulic press is made of alloy cast steel and it’s inner surface is finely grinded for life under high pressure. Four columns are made of alloy steel with high tensile resistance and finely grinded and electro-plated with hard chrome. Key hydraulic and electric units adopted are famous brands from Germany USA and Japan.

Hydraulic control uses the cartridge valve integrated system, reliable operation, long service life, small hydraulic impact, reduce the edge over road and leak. Independent of the electric control system, reliable operation, intuitive and easy maintenance. Fast approaching speed of movable working table creates higher production efficiency. Adopt centralized control buttons, with the adjustment, manual single cycle two kinds of operating mode.Through the selection of operation panel, which can realize the fixed distance and constant pressure two molding process, and have confirmed when rolling, and other functions.

Working pressure and stroke, according to the needs of process can be adjusted within the prescribed scope.

The deep drawing press is suitable for metal material drawing,bending,flanging,extruding as blanking process,as well as calibrating and press-fitting molding process of power abrasive and composite products.

| Model | Units | Specificatons | ||||||||||

| DSFS-50 | DSFS-120 | DSFS-220 | DSFS-220L | DSFS-275 | DSFS-350 | DSFS-350L | DSFS-500 | DSFS-500L | DSFS-600 | |||

| Master cylinder | Rated capacity | Ton | 35 | 85 | 160 | 160 | 200 | 260 | 260 | 350 | 350 | 420 |

| Max.stroke | mm | 350 | 450 | 560 | 560 | 560 | 560 | 560 | 600 | 600 | 700 | |

| Blank holding cylinder | Rated capacity | Ton | 15 | 35 | 60 | 60 | 75 | 90 | 90 | 150 | 150 | 180 |

| Max.stroke | mm | 175 | 200 | 260 | 260 | 260 | 600 | 260 | 300 | 300 | 350 | |

| Knocking out ejector | Rated capacity | Ton | 2 | 3 | 5 | 5 | 5 | 5 | 5 | 10 | 10 | 10 |

| Max.stroke | mm | 150 | 180 | 200 | 200 | 200 | 220 | 220 | 250 | 250 | 300 | |

| Open height | mm | 600 | 730 | 900 | 1000 | 900 | 900 | 900 | 1000 | 1200 | 1500 | |

| Height of fixed working table | mm | 990 | 1055 | 1080 | 1100 | 1100 | 1200 | 1200 | 1550 | 1600 | 1700 | |

| Approaching speed of M.W.T. | mm/s | 195 | 220 | 210 | 210 | 210 | 200 | 200 | 210 | 210 | 190 | |

| Drawing speed of M.W.T. | mm/s | 25 | 20 | 20 | 20 | 19 | 17 | 17 | 18 | 18 | 14 | |

| Returning speed of M.W.T. | mm/s | 180 | 220 | 200 | 200 | 200 | 165 | 165 | 190 | 190 | 180 | |

| Ascending speed of blank holding cylinder | mm/s | 120 | 50 | 120 | 120 | 115 | 160 | 160 | 85 | 85 | 75 | |

| Working table size available | L-R | mm | 500 | 500 | 710 | 900 | 800 | 900 | 1100 | 1050 | 1250 | 1400 |

| F-B | mm | 550 | 600 | 870 | 1100 | 900 | 1000 | 1250 | 1200 | 1500 | 1600 | |

| Over all dimension | L-R | mm | 1750 | 1990 | 20900 | 2280 | 2190 | 2200 | 2400 | 2970 | 3090 | 3690 |

| F-B | mm | 1160 | 1510 | 1500 | 1750 | 1650 | 1850 | 1850 | 2200 | 2400 | 2000 | |

| H | mm | 2550 | 2920 | 3500 | 3500 | 3600 | 3800 | 3840 | 4680 | 4800 | 5640 | |

| Motor power | kw | 7.5 | 15 | 30 | 30 | 30 | 37 | 37 | 55 | 55 | 55 | |

| Weight(Approx) | kg | 2280 | 3500 | 6000 | 6600 | 7500 | 9500 | 12500 | 16000 | 22000 | 23000 | |

TOP

TOP WINDOWS

WINDOWS