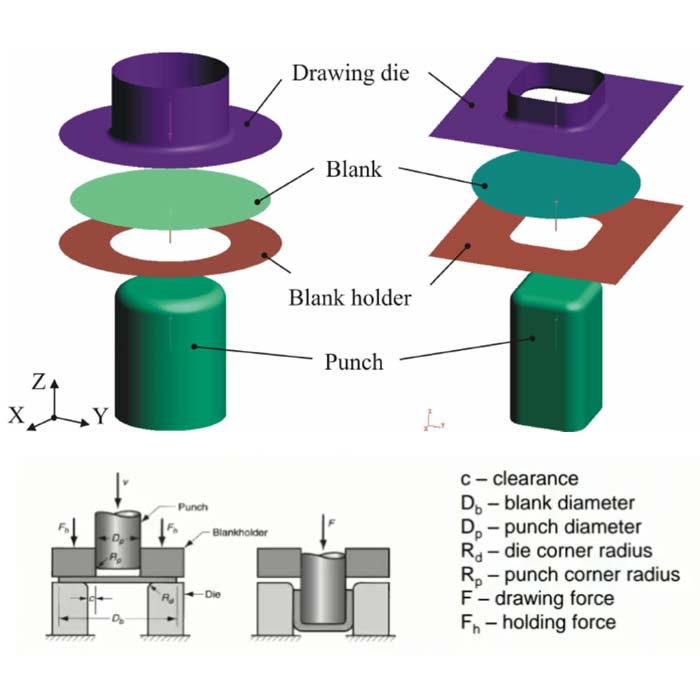

Deep drawing press process is quite challenging task to simulate due to requirement of multiple stages & precious tool design. Deep drawing is a sheet forming operation, in which the sheet is placed over the dieopening and is pushed by punch into the opening. The sheet is held flat on the die surface by using a blank.

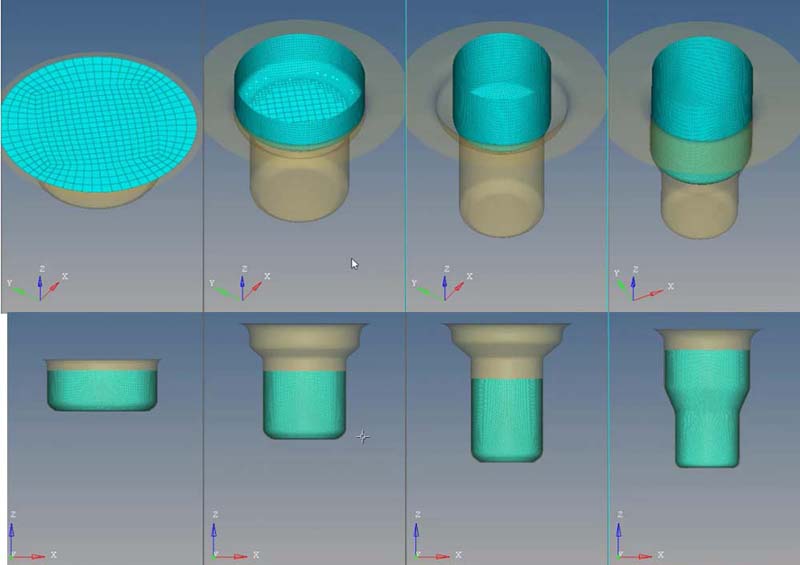

In the deep drawing process, the blank-holding force (BHF) is an important process parameter affecting the energy consumption and the successful production of parts. In the present work, both experiments and finite element simulations have been conducted to investigate the influence of constant and time variable BHF on drawing force(DF) and thickness distribution in the deep drawing process of cylindrical and square cups.A finite element model was developed in the AutoForm software and validated with experiments. The developed model has been used for the simulation of deep drawing process of AA6016-T4 aluminum alloy sheet. The experimental and numerical results show that, using a variable instead of a constant BHF, the DF can be decreased in the expense of wall thickening.

Our deep drawing press is suitable for metal material drawing, bending, flanging, extruding as blanking process, as well as calibrating and press-fitting molding process of power abrasive and composite products.If you need deep drawing press, please contact us email: [email protected] / [email protected].