Smart Hydraulic Presses with IoT & AI IntegrationUpdate:2025-05-21 Hits:58

The hydraulic press machine - a staple of heavy industry for over a century—is undergoing a digital revolution. With IoT (Internet of Things) and AI (Artificial Intelligence) integration, modern hydraulic presses are becoming smarter, more efficient, and predictive rather than reactive. Smart Hydraulic Presses with IoT & AI Integration: The Future of Precision Manufacturing

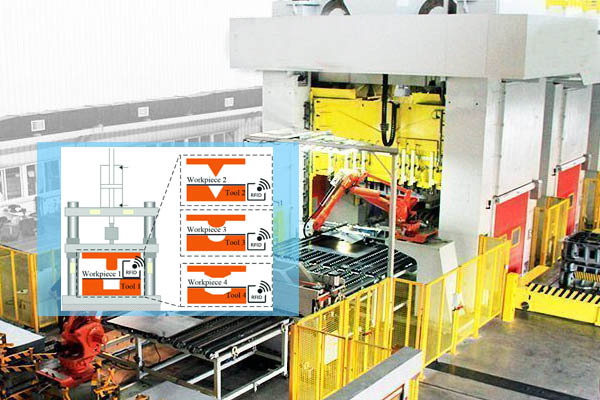

Smart hydraulic presses represent a significant advancement in manufacturing technology by integrating the power and precision of hydraulic systems with the connectivity of the Internet of Things (IoT) and the analytical capabilities of Artificial Intelligence (AI). This fusion creates machines that are not only powerful but also intelligent, efficient, and capable of adapting to production needs in real-time.

1. Real-Time Monitoring & Predictive Maintenance

● IoT sensors embedded in hydraulic presses continuously track:

● Pressure & force fluctuations

● Oil temperature & contamination levels

● Vibration patterns (detecting misalignment or wear)

Seal & component degradation

AI-driven analytics predict failures before they happen, reducing downtime by up to 40% (e.g., Schuler’s Connect 4.0 platform).

2. AI-Optimized Pressing Operations

● Adaptive force control: Machine learning adjusts pressure in real-time based on material properties (e.g., softer metals vs. composites).

● Energy efficiency: AI minimizes power consumption by optimizing pump usage.

● Self-correction: Detects anomalies (e.g., misaligned dies) and auto-corrects.

● Example: Bosch Rexroth’s AI Hydraulic Suite reduces scrap rates by 15-20% in automotive stamping.

3. Cloud-Based Remote Control & Digital Twins

● Operators monitor presses via cloud dashboards (e.g., Siemens MindSphere).

● Digital twin simulations test new setups virtually before physical production.

● Remote troubleshooting allows experts to diagnose issues from anywhere.

● Case Study: A German auto supplier cut 30% of on-site maintenance visits using IoT-enabled presses.

4. Smart Safety Features

● Computer vision (e.g., cameras + AI) stops the press if a worker's hand is too close.

● Collision avoidance systems for robotic loaders/unloaders.

● Automated emergency shutdowns if hydraulic pressure exceeds safe limits.

5. Future Trends

● 5G-enabled presses for ultra-low latency control.

● Blockchain-secured production logs for quality assurance.

● Fully autonomous self-learning hydraulic presses by 2030.

Why Choose Smart Hydraulic Presses?

✅ 30% less downtime (predictive maintenance)

✅ 20% energy savings (AI optimization)

✅ Near-zero defects (real-time adjustments)

Are you considering upgrading to a smart hydraulic press? The ROI justifies the shift—especially in automotive, aerospace, and battery manufacturing.

Last:Nothing