Four Elements for Selecting Hydraulic Press ParameterUpdate:2024-06-01 Hits:228

When we select the hydraulic press, in addition to choosing the appropriate brand hydraulic press model according to our own products, we also need to design and manufacture the most suitable hydraulic press for enterprise products from the nominal pressure (nominal tonnage) of the hydraulic press, the stroke of the hydraulic press, the opening height of the hydraulic press, and the size of the workbench of the hydraulic press.Nominal pressure of hydraulic press (tonnage)

The nominal maximum pressure (kN) that a hydraulic press can produce reflects the main working capacity of the hydraulic press.

The stroke of the hydraulic press

The stroke of the hydraulic press refers to the distance traveled by the piston from the top dead center to the bottom dead center. When operating the hydraulic press, the length of the stroke can be controlled by controlling the pressure of the hydraulic system according to the processing needs of the workpiece. The stroke of the hydraulic press is one of the important parameters that directly affects the quality and efficiency of machining.

Normally, the stroke of the hydraulic press needs to be set according to the size of the workpiece to be processed. Too little stroke can lead to under-processing, while too large stroke can increase machining time and energy consumption. Therefore, when using the hydraulic press, it is necessary to choose the length of the stroke according to the actual situation.

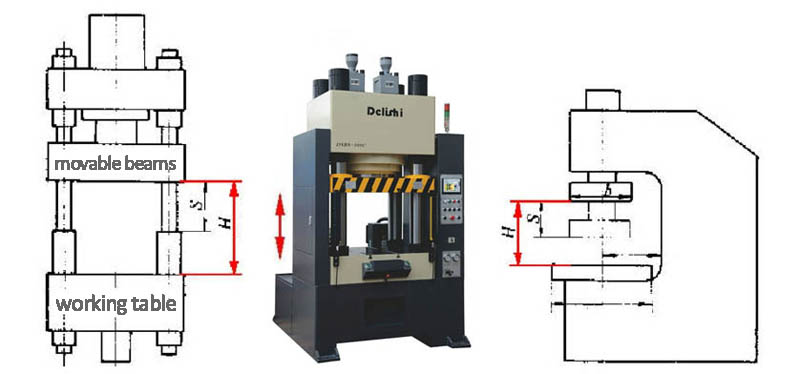

The open height of the hydraulic press

The opening of the hydraulic press refers to the maximum distance between the tables located in the middle of the guard of the hydraulic press. The size of the opening of the hydraulic press will directly affect the function and scope of use of the hydraulic press.

The size of the hydraulic press opening is usually selected according to the machining needs and the size of the workpiece. If the opening is too small, the workpiece cannot be put in and cannot be processed; If the opening is too large, it will affect the machining accuracy and efficiency, and increase the difficulty and cost of processing.

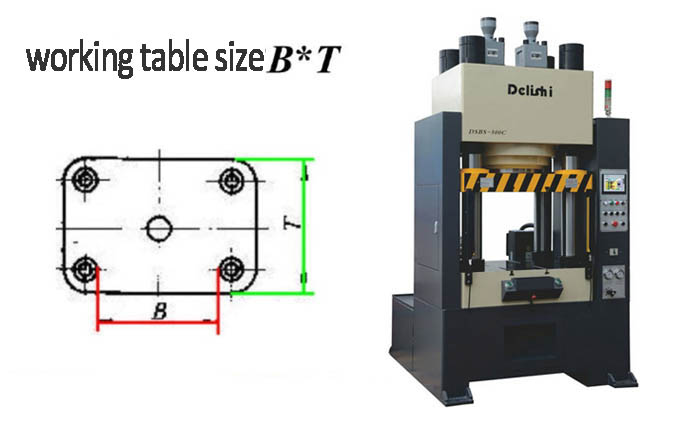

The working table size of hydraulic press

The size of the hydraulic press table refers to the effective size available on the table, which reflects the plane size of the hydraulic press working space.

The large forging or stamping hydraulic press is provided with a mobile workbench, and the size of the workbench refers to the effective plane size of the mobile workbench.

Since its establishment, the servo hydraulic press manufacturer - Tellis has been adhering to the spirit of craftsmanship for nearly 30 years, and is committed to improving the intelligence, applicability, durability and efficiency of hydraulic presses. If you have hydraulic press needs, please contact us to customize the hydraulic press solution that belongs to your enterprise products.