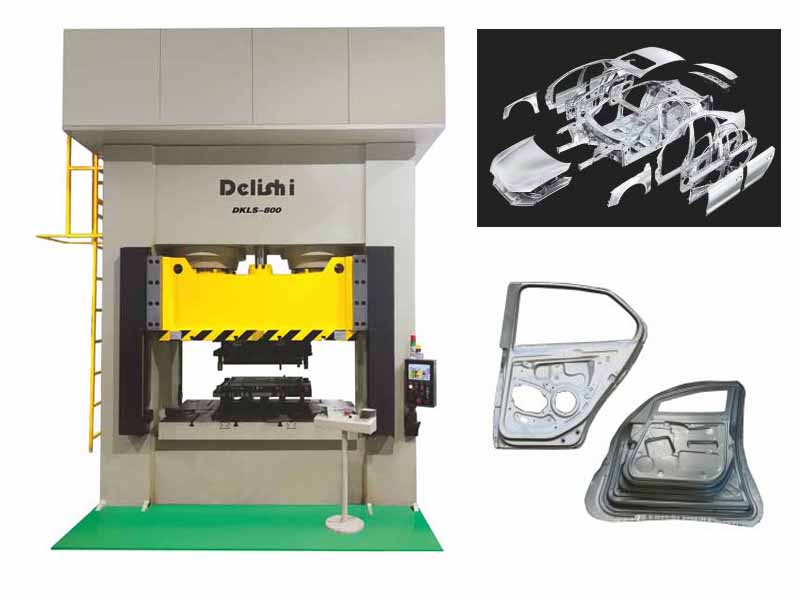

Frame Hydraulic Press Machine For Car DoorsUpdate:2021-11-02 Hits:331

The structure of car door sheet metal parts is complex, which affects the overall performance of the door. For the processing requirements of car doors, you can choose the automobile door sheet hydraulic deep drawing press, and the mold can realize the integral molding of the car door sheet metal. This hydraulic press machine adopts frame structure, which can significantly improve product quality. It is currently a popular way of processing car door sheet metal.

The processing technology of car door panels includes drawing, trimming and punching, flanging, and shaping. Each process requires a corresponding mold, and the basic shape of the car door panel is formed through the drawing process. Various tonnage of car door panel drawing hydraulic presses can be customized according to customer needs.Auto door panel hydraulic deep drawing press process

1. Cut the metal sheet to obtain a certain size of the car door blank.

2. The car door blank is stretched through the forming mold, so that the car door blank is stretched together to form the main board and the wall board located at the periphery of the main board and perpendicular to the main board, as well as two convex cavities symmetrically distributed on the main board. The convex cavity is used to install electrical components.

3. Turning a pair of positioning grooves on the outer surface of the main board, the pair of positioning grooves correspond to the two convex cavities one by one.

4. Punch out the sprout holes located in the two convex cavities through the automobile door panel drawing hydraulic press die.

5. Drill holes in the center of a pair of positioning grooves and on the wall.

6. Perform surface treatment on the workpiece that has completed the above steps.

7. The surface-treated workpiece is transported to the thermal laminating equipment through the conveying device, and the thermal laminating equipment is used to laminate the film on the outer surface of the workpiece.